Forklift maintenance is a strategic activity that goes far beyond simple mechanical care. In today’s industrial environment, it plays a crucial role in ensuring workplace safety, operational continuity, and legal compliance. More than that, a well-structured maintenance plan minimizes the risk of unexpected breakdowns, reduces unplanned costs, and protects long-term business investments.

But how should forklift maintenance be managed to be truly effective? In this article, we explore the key regulations, maintenance intervals, types of interventions, and the responsibilities involved—providing a complete overview for professionals in logistics, material handling, and industrial operations.

Why Is Forklift Maintenance So Important?

Proper forklift maintenance serves a dual purpose: preserving the equipment’s performance and ensuring operator safety. A forklift that is not properly inspected can pose serious risks to both workers and the surrounding environment, potentially leading to accidents, production downtime, and legal liabilities.

In contrast, a well-maintained forklift operates at peak efficiency, reducing fuel or energy consumption, improving handling precision, and extending the overall service life of the machine.

Forklift Maintenance Regulations: What Does the Law Say?

From a regulatory perspective, forklift maintenance is a legal obligation designed to ensure a safe working environment. According to Art. 194 of DPR 547/55, forklifts must undergo at least one general inspection per year. Furthermore, Legislative Decree 81/2008—Italy’s Consolidated Act on Health and Safety at Work—classifies forklifts as work equipment subject to routine inspections and upkeep. This obligation is also reinforced by ISPESL guidelines, which state that employers are responsible for scheduling and documenting maintenance activities.

The legislation highlights that there is no universal maintenance schedule, as each forklift model may have specific requirements outlined in the manufacturer’s manual. It is therefore up to the employer to ensure:

-

Regular inspections and safety checks

-

Replacement of worn or damaged components

-

Proper documentation of all maintenance activities carried out

Types of Forklift Maintenance: Periodic, Extraordinary, Daily

Scheduled Periodic Maintenance

Scheduled periodic maintenance forms the cornerstone of forklift safety and operational efficiency. It’s not merely a regulatory requirement—it’s a strategic investment to prevent breakdowns, extend equipment lifespan, and minimize costly downtime.

Scheduled periodic maintenance forms the cornerstone of forklift safety and operational efficiency. It’s not merely a regulatory requirement—it’s a strategic investment to prevent breakdowns, extend equipment lifespan, and minimize costly downtime.

During scheduled interventions, certified technicians perform comprehensive checks that go well beyond visual inspections. Every component—from engines and brakes to lift chains and safety systems—is tested and monitored. Particular attention is given to fast-wearing parts like forks, wheels, and drive systems.

Although regulations mandate at least an annual inspection, maintenance frequency can be adjusted based on usage intensity and operating environment. In high-demand settings, semi-annual or quarterly inspections may be advisable. The ultimate goal is to prevent critical failures and ensure forklifts remain fully operational and safe for use.

Extraordinary Maintenance

Even with planned care, unexpected breakdowns may occur. Extraordinary maintenance is the responsive action taken when a sudden malfunction or damage arises.

Even with planned care, unexpected breakdowns may occur. Extraordinary maintenance is the responsive action taken when a sudden malfunction or damage arises.

This critical intervention restores the forklift to full operational capability and may involve repairing mechanical parts, replacing damaged electronic components, or fixing structural damage caused by impact.

These tasks often require prompt diagnostics from highly qualified technicians, who can swiftly identify the root cause and provide the safest, fastest resolution—reducing both downtime and indirect costs associated with production stoppages.

Daily Maintenance (Pre‑Op Check)

A robust maintenance program begins with routine daily checks—an essential first defense against wear and surprise issues. Before each shift, operators conduct key inspections on their forklifts.

A robust maintenance program begins with routine daily checks—an essential first defense against wear and surprise issues. Before each shift, operators conduct key inspections on their forklifts.

First comes a visual check to spot fluid leaks, visible damage, or anomalies. Next, functionality tests ensure that brakes, lights, horns, and safety devices are all working properly. In electric forklifts, battery condition must also be checked regularly to avoid performance drops during operation.

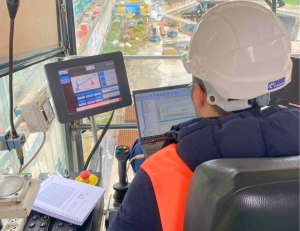

Digital tools like Linde MH’s Pre‑Op Check app are streamlining these procedures, enabling operators to perform and log checks via smartphones or tablets—enhancing traceability and overall management control.

Electric vs. Internal Combustion Forklifts: How Maintenance Differs

The nature of maintenance varies depending on the forklift’s power source. Electric forklifts, for example, require special attention to battery health, electrical connections, and charging systems. It’s essential to keep the battery in good condition, avoid deep discharges, and regularly inspect the charger.

On the other hand, internal combustion (IC) forklifts have different maintenance needs: care focuses on the combustion engine, fuel system, oil changes, filters, and exhaust system. Monitoring fluid levels and air intake quality is critical, especially in dusty or outdoor environments.

Despite these differences, several components always demand attention: chains, brakes, wheels, masts, and safety devices are critical parts regardless of the energy source.

Predictive Maintenance: Definition and Benefits

In recent years, traditional maintenance has been complemented by a new philosophy: predictive maintenance. The concept is simple—prevent failures by continuously monitoring the health of the forklift.

Thanks to sensors, intelligent software, and data analytics, it’s possible to accurately predict when a component is about to fail and take action before issues occur. This approach offers numerous benefits: reduced downtime; fewer emergency repairs; longer equipment lifespan; overall increased efficiency.

Combining predictive and preventive maintenance today represents the most effective management strategy for high-intensity industrial environments.

Forklift Maintenance: How Often Should Checks Be Performed?

One of the most common questions concerns the optimal frequency of maintenance. Here’s a simplified schedule:

One of the most common questions concerns the optimal frequency of maintenance. Here’s a simplified schedule:

-

Daily: visual inspections and functional tests by the operator

-

Every 3 months: lift chain inspections

-

Every 6–12 months: periodic maintenance by specialized technicians

-

In the event of a fault: immediate extraordinary maintenance

For other lifting equipment, such as mobile truck-mounted cranes, regulations require specific periodic inspections based on their service start date. As always, records and tracking of these interventions are essential for compliance during official inspections.

Who Can Perform Mandatory Forklift Maintenance?

Mandatory forklift maintenance must be performed by professionals with certified technical expertise. The employer is responsible not only for hiring qualified personnel but also for ensuring detailed documentation of every service performed and keeping it available for audits.

At the same time, it is crucial to recognize the role of trained operators. While they are not qualified to perform technical interventions, they significantly contribute through daily checks and reporting—such as monitoring fluid levels, battery status, and ensuring safety labels are in place.

Only a collaborative effort between operators and professional technicians can create a truly safe and productive working environment.

The Risks of Neglecting Forklift Maintenance

Failing to perform regular forklift maintenance leads to consequences that go far beyond technical malfunction. First and foremost, issues such as faulty brakes, hydraulic leaks, or worn-out forks can cause serious accidents, putting the safety of operators and nearby personnel at risk.

Beyond the danger of injury, businesses are exposed to severe financial and legal penalties, especially in the event of inspections or accidents resulting from poor maintenance practices.

Beyond the danger of injury, businesses are exposed to severe financial and legal penalties, especially in the event of inspections or accidents resulting from poor maintenance practices.

Neglecting maintenance also leads to more severe and costly breakdowns: a minor leak, if left unchecked, can escalate into prolonged equipment downtime, expensive repairs, and disruption to warehouse or production activities. Moreover, accelerated wear and tear on critical components like tires, chains, and engines shortens the forklift’s service life and significantly impacts overall operating costs.

Finally, the impact on a company’s reputation should not be underestimated: delays, safety incidents, or non-compliance with legal standards can undermine customer trust and strain relationships with business partners. In short, poor maintenance can become a ticking time bomb—leading to financial, legal, and reputational costs that far outweigh the investment in proper preventive care.

Reliability, Safety and Operational Continuity: Forklift Maintenance by 3Bmust

At 3Bmust International, we understand how essential it is to rely on lifting equipment that is always safe and efficient. That’s why our service department is highly specialized in the maintenance of all types of machinery in the sector, offering comprehensive support ranging from scheduled maintenance to emergency interventions.

Our scheduled maintenance plans are designed to anticipate potential issues, minimize the risk of downtime, and ensure optimal long-term performance. Every service is carried out in strict compliance with established protocols, with thorough inspections and meticulous attention to detail—because safety and efficiency must never be compromised.

Our scheduled maintenance plans are designed to anticipate potential issues, minimize the risk of downtime, and ensure optimal long-term performance. Every service is carried out in strict compliance with established protocols, with thorough inspections and meticulous attention to detail—because safety and efficiency must never be compromised.

When urgent action is required, our team is ready to respond quickly and effectively, minimizing downtime and ensuring the continuity of your operations. Thanks to the expertise and professionalism of our technicians, every machine is treated with the utmost care, ensuring reliable and lasting performance.

Contact us to learn how to optimize the manintenance of your equipment: fewer breakdowns, more safety, and constant productivity.

Your peace of mind is our priority, every single day.

No comment yet, add your voice below!